DESIGNED & MANUFACTURED FOR QUALITY

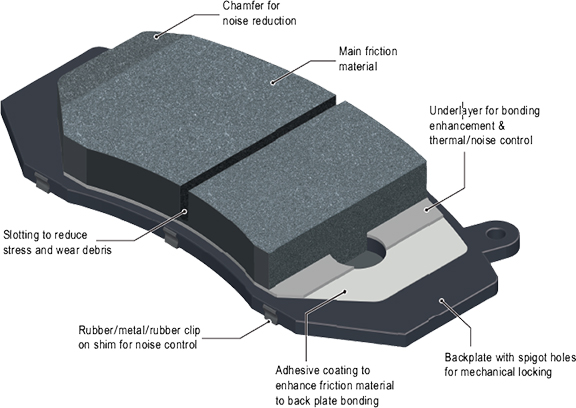

Working with OE clients has helped Allied Nippon hone brake

pad design and manufacturing to a truly exceptional standard.

As a result, Allied Nippon brake pads deliver genuine,

world-class performance.

With complete control over raw materials and the

manufacturing process we are able to ensure a consistency

of performance from each and every Allied Nippon pad.

Our NAM112A friction material is proven to deliver with

every push of the pedal; the excellent wear properties of

this compound ensures a long service life whilst the overall

construction of an Allied Nippon pad yields superior shear

strength and low noise properties.

RMR SHIM

Over 200 of the most popular Allied Nippon applications

feature the innovative RMR (Rubber-Metal-Rubber) clip-on

backing shim to help reduce noise and eliminate squeal.

This OE-type feature will be added to yet more applications

as part of an ongoing programme of product development.

‘E’ CERTIFIED PERFORMANCE

All Allied Nippon brake pads are ‘E’ certified under ECE R90

regulations. This EU directive governs brake pad design,

construction and performance, stipulating that a pad must

perform to within +/- 15% of the original part in a series of

stringent tests in order to comply. Buying R90 approved brake

pads is therefore the only way to ensure that you are supplying

safe, reliable products to the customer.

DEPTH OF RANGE

The Allied Nippon range is huge! In fact, we offer one

of the biggest ‘E’ certified brake pad ranges in the world!!!

In addition to covering over 95% of the European, Japanese

and Korean car parc, Allied Nippon also offers a complete

brake pad range for light commercial vehicles, trucks (CV),

buses and even trailers.